MAMTC Newsletter - December, 2018. Lego's Effect on Lean

“&@#$%!!! “

That’s the ‘statement’ made when an unsuspecting barefoot person steps on one of those curiously sharp and hard Lego blocks in the middle of the night. And what lesson did said person learn? Probably little and will likely question their decision to buy such a toy in the first place.

“Ah, I see it now.”

That’s the statement (or something like it) when a person uses a Lego in MAMTC’s Lego Airplane Factory Simulation Exercise.

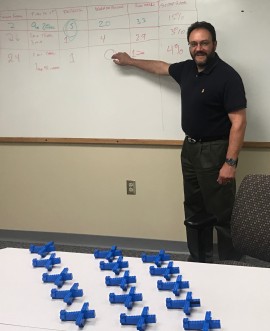

One of the most popular, informative and interactive parts of MAMTC’s Lean Foundations solution is the Lego Airplane Factory Simulation.

There is a lot of content that is presented as a part of the Lean Foundations solution. We have found that participants are able to better interpret, understand and relate to the content presented if they are able to visually and physically see the dramatic impacts that Lean can have on a manufacturing business. Thus, Legos.

There is a lot of content that is presented as a part of the Lean Foundations solution. We have found that participants are able to better interpret, understand and relate to the content presented if they are able to visually and physically see the dramatic impacts that Lean can have on a manufacturing business. Thus, Legos.

The purpose of the exercise is to have participants experience a typically poorly laid out factory, with work balance issues, excessive material handling, quality challenges and other factors to establish metrics around a Current State. Participants are then taught Lean Foundations and tools along with a discussion of how those lessons can be utilized to improve the Lego Airplane Factory.

After that, the participants are given time to have a Kaizen event where they ideate, pilot, verify and implement their improvement suggestions to improve upon the Current State.

The exercise is meant to demonstrate how Current Conditions usually are and how with some guidance and foundational knowledge in Lean, significant improvements can be made. It encourages teamwork, experimentation, including the Plan-Do-Check-Act (PDCA) cycle.

We have facilitated this full-day exercise numerous times with manufacturers spanning multiple industries including automotive, aerospace, plastics, consumer products farming equipment. Participants have included shop floor workers, production leadership, plant management, and administrative support. We have even facilitated this in a non-manufacturing setting with a Lean group at a local area hospital. Each time has yielded very different results in terms of how the teams have improved their factory. Yet a few things remain constant –

We have facilitated this full-day exercise numerous times with manufacturers spanning multiple industries including automotive, aerospace, plastics, consumer products farming equipment. Participants have included shop floor workers, production leadership, plant management, and administrative support. We have even facilitated this in a non-manufacturing setting with a Lean group at a local area hospital. Each time has yielded very different results in terms of how the teams have improved their factory. Yet a few things remain constant –

- Participants have fun while learning

- They see how this process has applications to their current operations

- Despite the significant improvements made, they want more time to make even more improvements

- They want others in their organization to experience the same exercise

And most importantly, no one has ever stepped barefoot on an errant Lego piece.

Conact MAMTC to discuss how MAMTC's Lean Foundations solution (and Legos) can help your manufacturing business improve.

Joe Torrago is a Director based in MAMTC’s Overland Park Office, specializing in the technologies of the Lean Enterprise and Supply Chain Optimization.

Joe has over 25 years of industry experience in manufacturing plants in either a technical support or operations leadership role and many years of experience playing with Legos.

LEAN SOLUTIONS