Automation vs. Digitization

Automation vs. Digitization in Manufacturing: Understanding the Difference

In the era of Industry 4.0, manufacturers are embracing a wide range of technologies to improve efficiency, quality, and agility. Two of the most discussed concepts are automation and digitization. While they often go hand in hand, understanding the difference between them is essential for any business aiming to build a truly smart factory.

What Is Automation?

Automation is all about performing tasks with minimal human input. This includes the use of:

- Robotics for assembly and packaging

- CNC machines for precision machining

- Programmable Logic Controllers (PLCs) for process control

The primary benefits of automation are:

- Increased production speed

- Improved consistency and quality

- Lower labor costs and reduced error rates

By taking over repetitive or dangerous tasks, automation allows workers to focus on higher-value activities.

What Is Digitization?

Digitization refers to converting analog information or manual processes into digital formats. In manufacturing, this could involve:

-

Using sensors to collect equipment performance data

- Storing maintenance records in cloud-based systems

- Visualizing production metrics through real-time dashboards

The primary enefits of digitization include:

- Better data visibility and accessibility

- Faster, data-driven decision-making

- Enhanced ability to monitor and improve operations remotely

How They Work Together

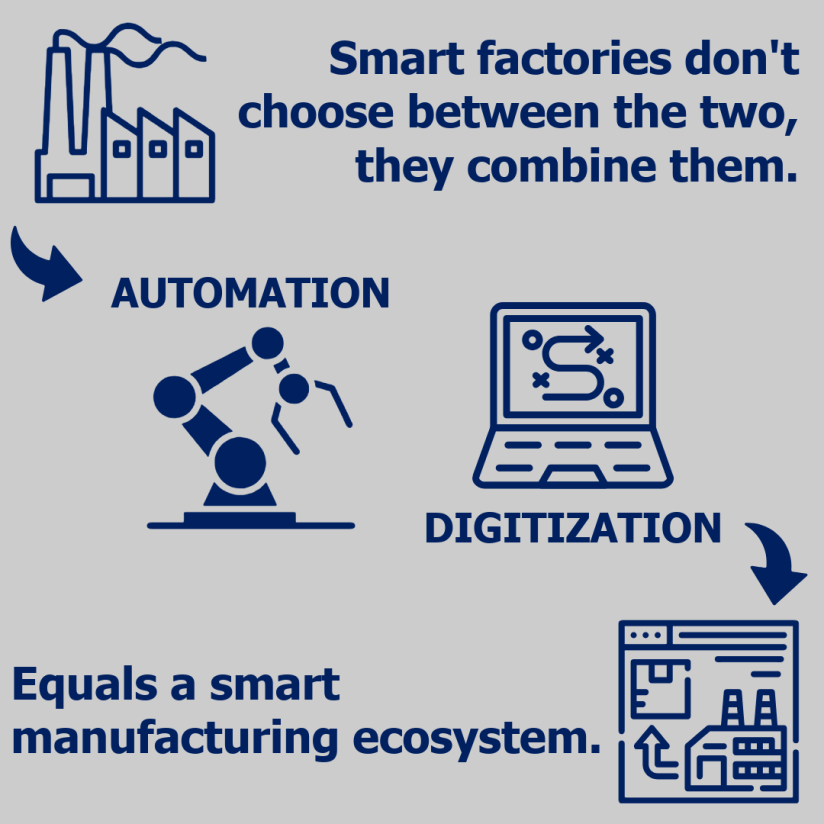

Think of automation as the "hands" and digitization as the "brain" of a smart factory. Automation carries out the tasks, while digitization provides the information and context needed to make them smarter.

When combined, they enable:

- Predictive maintenance using real-time machine data

- Dynamic quality control adjustments during production

- Full digital traceability of products from raw material to finished good

This integration forms the backbone of smart manufacturing, powered by technologies like AI (artificial intelligence), IoT (internet of things), and digital twins.

Conclusion

While automation makes manufacturing faster and more efficient, digitization makes it smarter and more responsive. Together, they pave the way for truly intelligent operations that can adapt, learn, and continuously improve.